Tổng số phụ: 0₫

- FUJI

- Tài liệu

- BIẾN TẦN NHẬT BẢN

- News

- BIẾN TẦN TRUNG QUỐC

- YASKAWA

- EASYDRIVE

- Máy nén khí

- ESTUN

- Ngành bao bì nhựa

- FRECON

- Bơm - quạt

- INOVANCE

- Bao bì - Nhựa

- INVT

- SENLAN

- SIEMENS

- SHIHLIN

- Cầu trục-cẩu trục nâng hạ

- V&T

- MITSUBISHI

- VEICHI

- ABB

- Dệt - Nhuộm

- Lò hơi công nghiệp

- GIẢI PHÁP

- Máy cắt đuổi - Cắt quay

- Tin công nghệ

- Tin tức

- Tuyển dụng

Modernization of Lead-Zinc Mine Hoist Utilizing HOPE800 VFD

This report presents the successful case study of implementing the SLANVERT HOPE800G280T4 frequency converter to modernize the speed control system of a lead-zinc mine hoist. The project aimed to address the inherent inefficiencies and limitations associated with the traditional wound motor employing rotor series resistance control.

Background:

Mine hoists play a critical role in ensuring efficient and safe material and personnel transport within vertical and inclined mine shafts. However, conventional rotor series resistance control methods for wound motors suffer from several drawbacks:

- Energy Inefficiency: Significant slip power loss occurs at low speeds, resulting in wasted electrical energy.

- Control Limitations: Restricted control over hoist speed and operation can hinder smooth and efficient material handling.

- Maintenance Burdens: Frequent contact wear and tear within the electrical control system necessitate regular maintenance interventions.

Solution:

The SLANVERT HOPE800G280T4 frequency converter offers a robust and technologically advanced solution to overcome these challenges. This high-performance vector control drive provides:

- Precise Torque Control: Advanced vector control algorithms ensure accurate torque control throughout the entire speed range, enabling smooth and efficient hoist operation.

- Energy Savings: By eliminating slip power losses, the frequency converter delivers significant energy cost reductions. The estimated energy savings in this project are anticipated to be around 24.5%.

- Soft Start/Stop Functionality: Controlled acceleration and deceleration profiles minimize mechanical stress on the hoist and motor, extending equipment lifespan and reducing maintenance requirements.

- Enhanced Reliability: The solid-state design of the frequency converter minimizes wear and tear on electrical components, leading to improved system reliability.

- Operator Control: The implementation of a self-aligning angle machine provides operators with precise speed control capabilities, optimizing material handling efficiency.

Project Implementation:

A meticulous approach was undertaken to ensure the successful integration of the frequency converter into the existing hoist system. Key considerations included:

- Load Analysis: The hoist’s load characteristics were identified as constant torque, requiring smooth acceleration and deceleration during loaded and unloaded operation.

- Regenerative Braking Management: A dedicated energy consumption braking unit with a braking resistor was incorporated to handle regenerative energy generated during braking, particularly when lowering empty buckets.

- Safety Measures: To prioritize safety, an increased motor capacity (280kW) was selected to accommodate potential overload scenarios. The existing braking system remained operational during the conversion, with the frequency converter maintaining control below 0.3Hz to ensure safe operation.

- Control System Modification: The original cam controller was repurposed to control hoist direction, while a self-aligning angle machine was installed to translate joystick movements into precise analog voltage signals for the frequency converter.

- Frequency Converter Configuration: Optimal performance was achieved by meticulously configuring specific parameters on the HOPE800G280 to perfectly align with the unique requirements of the hoist application.

Outcomes and Benefits:

The successful implementation of the SLANVERT HOPE800 frequency converter has yielded significant improvements for the lead-zinc mine hoist operation:

- Reduced Energy Consumption: The project has demonstrably lowered energy costs through improved system efficiency.

- Enhanced Reliability: Minimized downtime and maintenance needs contribute to increased operational productivity.

- Extended Equipment Lifespan: Reduced wear and tear on the hoist and motor translate to longer equipment life and lower replacement costs.

- Improved Operator Control: Precise speed control capabilities empower operators to optimize material handling processes.

- System Flexibility: The ability to revert to the original power frequency system, if necessary, offers additional operational flexibility.

Conclusion:

This project serves as a compelling testament to the effectiveness of variable frequency speed control technology in modernizing mine hoist operations. The implementation of the SLANVERT HOPE800G280 frequency converter has resulted in substantial improvements in energy efficiency, operational control, equipment longevity, and overall cost savings for the lead-zinc mine.

Nguồn: https://www.slanvert.com.cn/solutions

Mua biến tần Senlan giá tốt, chính hãng ở đâu?

B&V Việt Nam – Đại lý chính thức của SENLAN tại Việt Nam. Các dòng sản phẩm biến tần SenLan cung cấp như: Hope130, Hope530, SB200,… B&V Việt Nam tự tin là đơn vị đồng hành cùng Quý khách hàng trong các dự án tự động hóa với:

- Sản phẩm đa dạng và đạt chuẩn chất lượng quốc tế

- Hàng hóa có sẵn số lượng lớn tại kho

- Thời gian giao hàng nhanh, linh hoạt

- Dịch vụ bảo hành chính hãng, chuyên nghiệp, tận tâm.

- Hỗ trợ tư vấn 24/7

Để được hỗ trợ và tư vấn thêm về sản phẩm vui lòng liên hệ Hotline 0988 658 790 để được giải đáp.

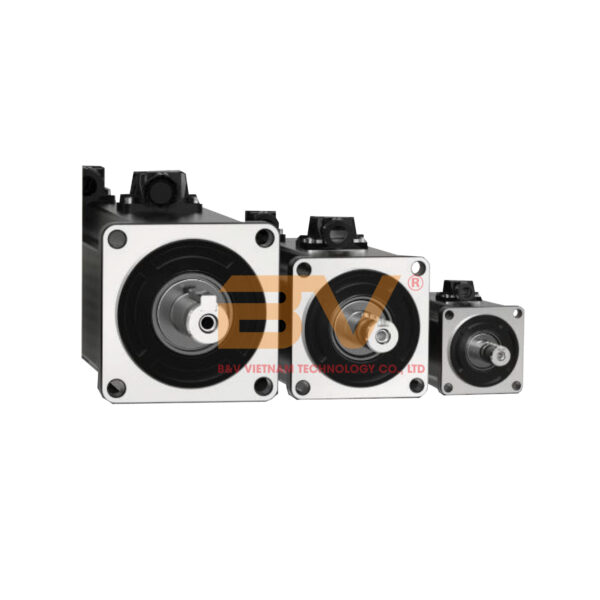

Servo Motor Slanvert KMTM130-13C15E□-BOK, 1300W, 220V

Servo Motor Slanvert KMTM130-13C15E□-BOK, 1300W, 220V