Tổng số phụ: 0₫

- FUJI

- Tài liệu

- BIẾN TẦN NHẬT BẢN

- News

- BIẾN TẦN TRUNG QUỐC

- YASKAWA

- EASYDRIVE

- Máy nén khí

- ESTUN

- Ngành bao bì nhựa

- FRECON

- Bơm - quạt

- INOVANCE

- Bao bì - Nhựa

- INVT

- SENLAN

- SIEMENS

- SHIHLIN

- Cầu trục-cẩu trục nâng hạ

- V&T

- MITSUBISHI

- VEICHI

- ABB

- Dệt - Nhuộm

- Lò hơi công nghiệp

- GIẢI PHÁP

- Máy cắt đuổi - Cắt quay

- Tin công nghệ

- Tin tức

- Tuyển dụng

Application of SBH series medium voltage frequency inverter in dust removal fan in steel rolling mill

1. Preface

Steel rolling mills, with their resource-intensive, energy-intensive, large-scale production, and large logistics throughput characteristics, have long been considered enterprises with large amounts of smoke emissions, waste, and pollution. Electric arc furnace steelmaking is one of the main sources of smoke pollution in some steel rolling mills. The arc furnace will produce a large amount of high-temperature flue gas during the smelting process. If it is not collected and processed, it will cause very serious air pollution. In recent years, with the improvement of smelting technology, the smelting rhythm has been greatly accelerated, the oxygen consumption of electric arc furnaces has increased sharply, which has brought about a doubling of the amount of flue gas generation, and the processing capacity of dust removal facilities has been continuously improved and increased. At the same time, flue gas dust removal facilities are used as auxiliary equipment in steelmaking enterprises, which have the characteristics of large energy consumption and high operating costs. For a long time, no matter which operating stage the electric furnace is in, the size of the flue gas dust generated causes the dust removal fan to run at full speed, and the inlet baffle opening is used to adjust the opening. This low efficiency results in a large amount of waste of electrical energy.

2. Background

A certain steel rolling mill is a large private enterprise. The main product is rebar, with an annual production capacity of approximately 700,000 tons. There are four medium-sized steel rolling production lines, one 800# rolling mill production line, one 650# rolling mill production line and two 500# rolling mill production lines. The electric furnace is a 10t eccentric AC electric furnace, and the dust collector system uses a pulse bag dust collector. Since the motor is a 900kW medium-voltage motor, it is very difficult to start the motor every time it is running at power frequency. Unless there are special circumstances, the medium-voltage motor is generally not stopped. That is to say, the dust removal fan is generally not stopped during maintenance of the electric furnace, and the motor is always running with load. , the power consumption is very wasteful. As market competition continues to intensify, saving energy, reducing consumption, and improving production efficiency have become one of the effective means for enterprise development and improvement of competitiveness. Based on the above reasons, the factory required the dust removal fan to be modified.

3. Operating Conditions

The harmful pollution produced during electric furnace steelmaking is mainly reflected in the three stages of electric furnace charging, smelting and tapping. Electric furnace smelting is generally divided into a melting period, an oxidation period and a reduction period. The oxidation period strengthens decarburization and produces a large amount of thick smoke due to oxygen blowing or ore addition. Among the above three smelting periods, the oxidation period produces the largest amount of flue gas, with the highest dust concentration and flue gas temperature. Therefore, the electric furnace dust removal system is designed according to the maximum smoke emission during the oxidation period. The oxygen blowing period accounts for 30~35% of the entire steelmaking process. At this time, the fan is operating at a higher load, while the rest of the time is at a lower operating condition.

4. Modification Proposal

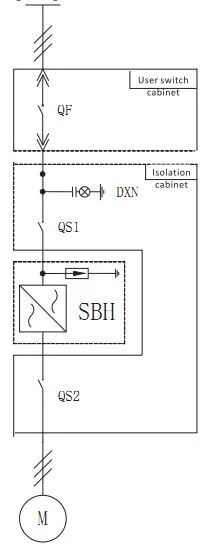

The variable frequency control of dust removal fan is the most basic one-to-one control. The control scheme is as shown in the figure below:

QF: User-side medium voltage vacuum circuit breaker with integrated relay protection device.

QS1, QS2, QS3, manual switch. Among them, QS2 and QS3 have mechanical interlocks and cannot be closed at the same time.

Switch-on QS1, QS2, and Switch -off QS3 for frequency conversion control mode. The motor can be controlled by a frequency inverter to regulate speed.

Switch-on QS3,Switch-off QS1 and QS2 are power frequency mode. The motor can be started, stopped and protected directly by QF, and the frequency converter can be completely disconnected from the power grid for easy maintenance and inspection.

5. System Modification Plan

After applying medium-voltage frequency converter speed control, a control method that combines opening and closing valves with dust removal fan speed adjustment can be used. Due to the requirements of the production process, the dust removal fan needs to stop dust removal during ironmaking and start dust removal when tapping. Therefore, the frequency converter speed regulating device runs at low speed during ironmaking and at high speed when tapping. When all the taphole dust collection hood valves are fully opened, the fan runs at the highest speed. In other cases, on the premise of ensuring the dust removal effect of each hood, the fan speed is automatically adjusted according to the opening and closing of the hood valve to minimize the fan speed. speed, the purpose of saving electric energy can be achieved.

The main signals between the inverter control system and the site are shown in the following table

| Serial number (s) | Singal definition | Type of product | Serial number (s) | Singal definition | Type of product |

| 1 | Flue valve on/off | DI | 4 | Fan up and running | DI |

| 2 | Swimming pool | DI | 5 | Stop the fan | DI |

| 3 | Iron casting signal | DI | 6 | The alarm goes off | DO |

6. System features and anergy saving results

1) Remarkable energy saving, which greatly reduces the power consumption and the power saving rate is about 30%.

2) Available for soft start of the motor

3) Maintenance workload and maintenance costs are reduced.

4) It has a wide speed range and high precision, and the air volume of the dust removal fan can be changed according to process needs.

5) SLANVERT medium-voltage inverter has multiple protection functions such as overcurrent, short circuit, overvoltage, undervoltage, phase loss, and temperature rise protection. It performs complete and better protection of the motor.

6) Improve operating conditions and reduce labor intensity of workers.

Nguồn: https://www.slanvert.com.cn/solutions

Mua biến tần Senlan giá tốt, chính hãng ở đâu?

B&V Việt Nam – Đại lý chính thức của SENLAN tại Việt Nam. Các dòng sản phẩm biến tần SenLan cung cấp như: Hope130, Hope530, SB200,… B&V Việt Nam tự tin là đơn vị đồng hành cùng Quý khách hàng trong các dự án tự động hóa với:

- Sản phẩm đa dạng và đạt chuẩn chất lượng quốc tế

- Hàng hóa có sẵn số lượng lớn tại kho

- Thời gian giao hàng nhanh, linh hoạt

- Dịch vụ bảo hành chính hãng, chuyên nghiệp, tận tâm.

- Hỗ trợ tư vấn 24/7

Để được hỗ trợ và tư vấn thêm về sản phẩm vui lòng liên hệ Hotline 0988 658 790 để được giải đáp.

Servo Motor Slanvert KMTM100-10C30E□-BOK, 1000W, 220V

Servo Motor Slanvert KMTM100-10C30E□-BOK, 1000W, 220V